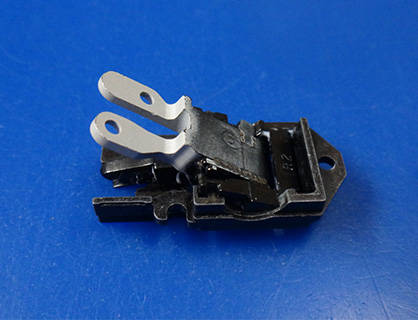

We have succeeded in producing parts that require high precision, such as optical pickup parts for DVD recorders (parts that read DVD information with a laser), by high-precision casting using zinc die casting, which was previously considered difficult. As a result, a monthly supply of more than 10 million units has been steadily achieved, with a global market share of 30%. In addition, our zinc die casting products are also used in parts of German high-end automobiles and controller stick parts of popular home-use game machines, and among the screw parts for antennas delivered to global mobile phone manufacturers, they are the global standard. There is also one.

|

We not only produce by casting only, we believe that the mold holds the goodness of the casting, we cultivate the know-how of precision design and manufacturing of the mold, and continue to manufacture higher quality products to meet the needs of our customers. It is intended to be deployed in. Above all, it is good at predicting the flow of zinc from the drawing by flow analysis and recognizing sinks and places where welds are likely to occur during molding before molding, thereby creating precise and reliable products. Furthermore, we have absolute confidence in quality control and have obtained ISO 9001 and ISO 14001. Please leave high precision and high quality zinc die casting. |

|---|

|

Substantial cost reduction can be expected by substituting zinc die-cast for precision products and parts that could only be manufactured with a metal frame such as stainless steel. We have received many inquiries regarding further cost reductions and have a large track record. If you have a suggestion to improve cost performance, leave it to Horio Seisakusho. |

|---|